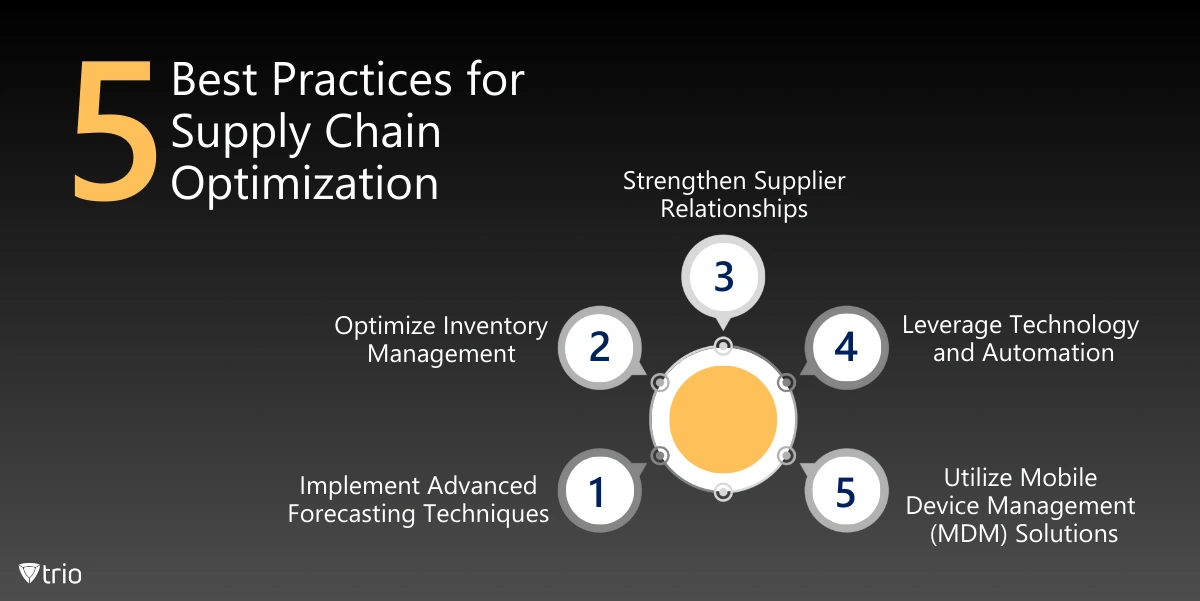

Effective supply chain optimization is crucial for maintaining a competitive edge in today's fast-paced business environment. Streamlining operations not only reduces costs but also enhances customer satisfaction by ensuring timely delivery of products and services. Here are five essential supply chain optimization techniques and tips to help you optimize your supply chain.

-

Implement Advanced Forecasting Techniques

Accurate forecasting is the foundation of a well-optimized supply chain. Traditional methods like historical data analysis are no longer sufficient due to the dynamic nature of modern markets. Instead, businesses should adopt advanced forecasting techniques, including machine learning algorithms and predictive analytics.

Machine learning models can be used as supply chain optimization tools to analyze vast amounts of data to identify patterns and trends that humans might miss. According to McKinsey & Company, “Applying AI-driven forecasting to supply chain management can reduce errors by between 20 and 50 percent.” By integrating these models, businesses can predict demand more accurately, reducing the risks of overstocking or stockouts. Additionally, predictive analytics can help companies anticipate market changes and adjust their strategies proactively.

Collaborative forecasting, which involves sharing data and insights with suppliers and partners, can further enhance network optimization in supply chains. This approach ensures that all stakeholders have a unified view of demand expectations, enabling better coordination and planning across the supply chain.

-

Optimize Inventory Management

Effective inventory management balances the need to meet customer demand with the necessity of minimizing carrying costs. One of the most effective ways to achieve this balance is through the implementation of Just-In-Time (JIT) inventory systems.

JIT inventory management is an example of supply chain optimization that ensures that materials and products are received just as they are needed in the production process, thereby reducing inventory holding costs. This approach requires close collaboration with suppliers to ensure timely delivery and quality assurance. It also necessitates robust internal processes to manage production schedules effectively.

In addition to JIT, leveraging technology such as inventory management software can provide real-time visibility into stock levels, helping businesses make informed decisions regarding supply optimization. Advanced systems can automate reordering processes, generate alerts for low stock levels, and even predict future inventory needs based on current trends and historical data.

-

Strengthen Supplier Relationships

Strong supplier relationships are vital for a resilient and responsive supply chain. Building and maintaining these relationships can lead to better pricing, improved quality, and more reliable deliveries. Start by selecting suppliers who are not only cost-effective but also align with your company's values and goals.

Regular communication with suppliers is crucial. This can be achieved through frequent meetings, performance reviews, and joint planning sessions. Transparent communication helps in quickly addressing any issues that arise and fosters a sense of partnership and mutual respect.

Investing in supplier development programs can also be beneficial. These programs might include training sessions, joint innovation initiatives, or financial support for suppliers to improve their capabilities. By helping your suppliers grow, you can enhance their performance and reliability, ultimately benefiting your entire supply chain.

-

Leverage Technology and Automation

Incorporating the latest technology and automation into your supply chain operations can significantly enhance efficiency and accuracy. Technologies such as Internet of Things (IoT) devices, artificial intelligence (AI), blockchain, and supply chain optimization software are transforming supply chain management.

IoT devices can provide real-time tracking and monitoring of goods, offering insights into their condition and location at any given time. This level of visibility helps in managing logistics more effectively and responding swiftly to any disruptions.

AI-powered supply chain network optimization software can optimize various aspects of the supply chain, from demand forecasting to route planning. These systems analyze large datasets to identify the most efficient ways to allocate resources and schedule deliveries. Additionally, blockchain technology ensures transparency and security in transactions, reducing the risk of fraud and errors.

Automation of routine tasks, such as order processing and inventory updates, frees up human resources for more strategic activities. Automated systems also reduce the likelihood of human error, ensuring more accurate and consistent operations.

-

Utilize MDM Solutions

The rise of mobile technology has revolutionized supply chain operations, providing greater flexibility and real-time access to critical information. Mobile Device Management (MDM) solutions are essential for optimizing the use of mobile devices within your supply chain.

MDM solutions enable businesses to monitor, manage, and secure mobile devices used by their workforce. This is particularly important for supply chain operations, where employees often use mobile devices to track inventory, manage deliveries, and communicate with team members. With MDM, companies can ensure that these devices are used efficiently and securely by enabling specific features such as using kiosk modes.

Implementing an MDM solution allows for centralized control over all mobile devices, ensuring they are up to date with the latest software and security protocols. This reduces the risk of data breaches and ensures compliance with industry regulations. Moreover, MDM solutions can help in quickly locating and recovering lost or stolen devices, minimizing the potential impact on operations.

MDM also enhances productivity by enabling remote access to essential supply chain management tools and data. Employees can perform their tasks from anywhere, allowing for greater flexibility and faster response times. This real-time access to information helps in making informed decisions promptly, further streamlining supply chain processes.

Conclusion

In conclusion, optimizing your supply chain requires a multifaceted approach that includes advanced forecasting, efficient inventory management, strong supplier relationships, leveraging technology, and utilizing MDM solutions. An MDM solution we suggest you try out to increase operational efficiency is Trio. Trio can streamline operations in various industries and be used to optimize supply chains. Try out Trio’s free demo to see its capabilities for yourself!

Get Ahead of the Curve

Every organization today needs a solution to automate time-consuming tasks and strengthen security.

Without the right tools, manual processes drain resources and leave gaps in protection. Trio MDM is designed to solve this problem, automating key tasks, boosting security, and ensuring compliance with ease.

Don't let inefficiencies hold you back. Learn how Trio MDM can revolutionize your IT operations or request a free trial today!